Semiconductor Industry

Precision temperature control is an essential component in Semiconductor manufacturing. As wafer technology continues to advance, the need for temperature accuracy becomes ever more crucial. Whether your process be material removal, deposition, growth, or testing, temperature plays a crucial role. In an industry dominated by efficiency, the same standard should be expected in your temperature control equipment.

Typical Applications

Wafer Etching

Chemical Vapor Deposition (CVD)

Physical Vapor Deposition (PVD)

Water baths for variable use in biological, medical or biochemical laboratories for temperatures from 25 to 100 °C. Shaking water baths from 10 to 99.9 °C for the lab.

Shaking water baths of the LAUDA Hydro series move samples in the laboratory with a linear or orbital shaking movement, depending on the model. LAUDA Hydro shaking water baths are reliable companions for continuous operation in daily laboratory work.

Application examples

- Bacteriological examinations

- Molecular biology

- Demulsibility studies

- Processing chemical reactions

- Thawing

- Metallurgical analysis

- Incubation of microbiological assays

- Warming Reagents

- Environmental studies

- Food processing (QC)

- Water quality research

- Cytochemistry

Working temperature min.

25 °C

Working temperature max.

100 °C

Efficiency Driven by Sustainability and Cost Savings

LAUDA-Noah SEMISTAT

Eco-Friendly: Refrigerant free (reducing GWP), exploring non- PFAS fluid options for sustainability.

Energy Efficient: Consumes less power than traditional units, minimizing operating costs.

Minimal Fluid Usage: 2.5L fluid reservoir reduces consumption, thereby reducing operating cost.

TE Technology: Operates efficiently, using power only under load.

Maintenance Advantage: Virtually maintenance-free with a single moving part, the pump.

Water baths for variable use in biological, medical or biochemical laboratories for temperatures from 25 to 100 °C. Shaking water baths from 10 to 99.9 °C for the lab.

Shaking water baths of the LAUDA Hydro series move samples in the laboratory with a linear or orbital shaking movement, depending on the model. LAUDA Hydro shaking water baths are reliable companions for continuous operation in daily laboratory work.

Application examples

- Bacteriological examinations

- Molecular biology

- Demulsibility studies

- Processing chemical reactions

- Thawing

- Metallurgical analysis

- Incubation of microbiological assays

- Warming Reagents

- Environmental studies

- Food processing (QC)

- Water quality research

- Cytochemistry

Working temperature min.

25 °C

Working temperature max.

100 °C

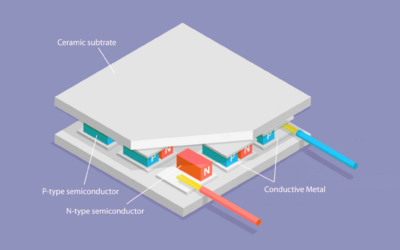

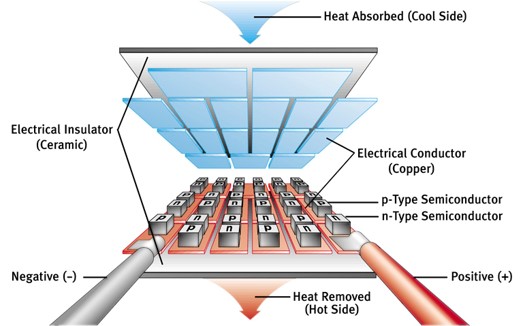

Thermoelectric (TE) System

Each module consists of p-type and n-type semiconductor pellets positioned between two ceramic plates. The pellets are connected in series electrically, and connected in parallel thermally. When a voltage is applied to a TE module, heat is transferred, or “pumped” from one side to the other. The effect is to rapidly cool one side and heat the other. Reversing polarity reverses the heat transfer direction, enabling a module to both heat and cool.

- No Moving Parts or Refrigerants: Enhancing reliability and reducing maintenance.

- Scalable Cooling: Increase cooling capacity with added modules.

- Efficient Control: Precisely regulating cooling and heating power through current modulation.

- Responsive Temperature Adjustment: Rapidly adapt to process temperature changes.

- Versatile Operation: Seamlessly transition between cooling and heating modes by changing polarity, eliminating the need for a heater.

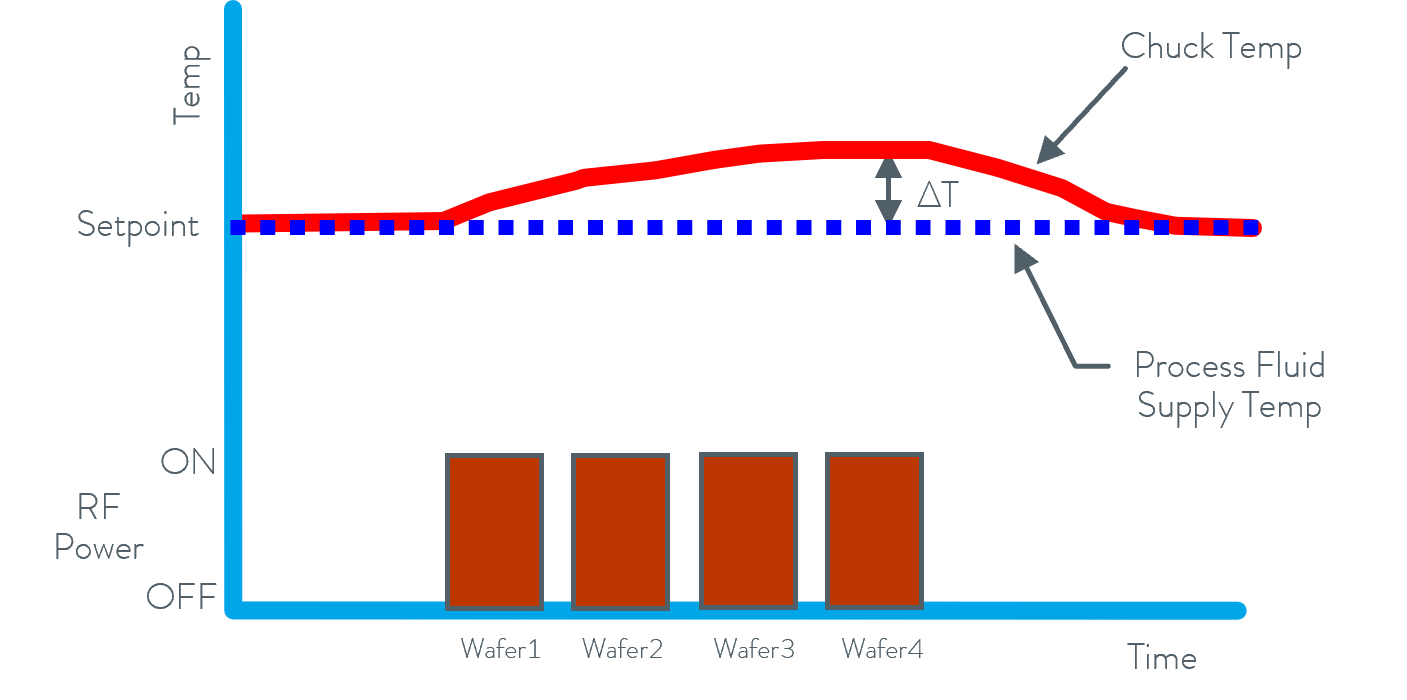

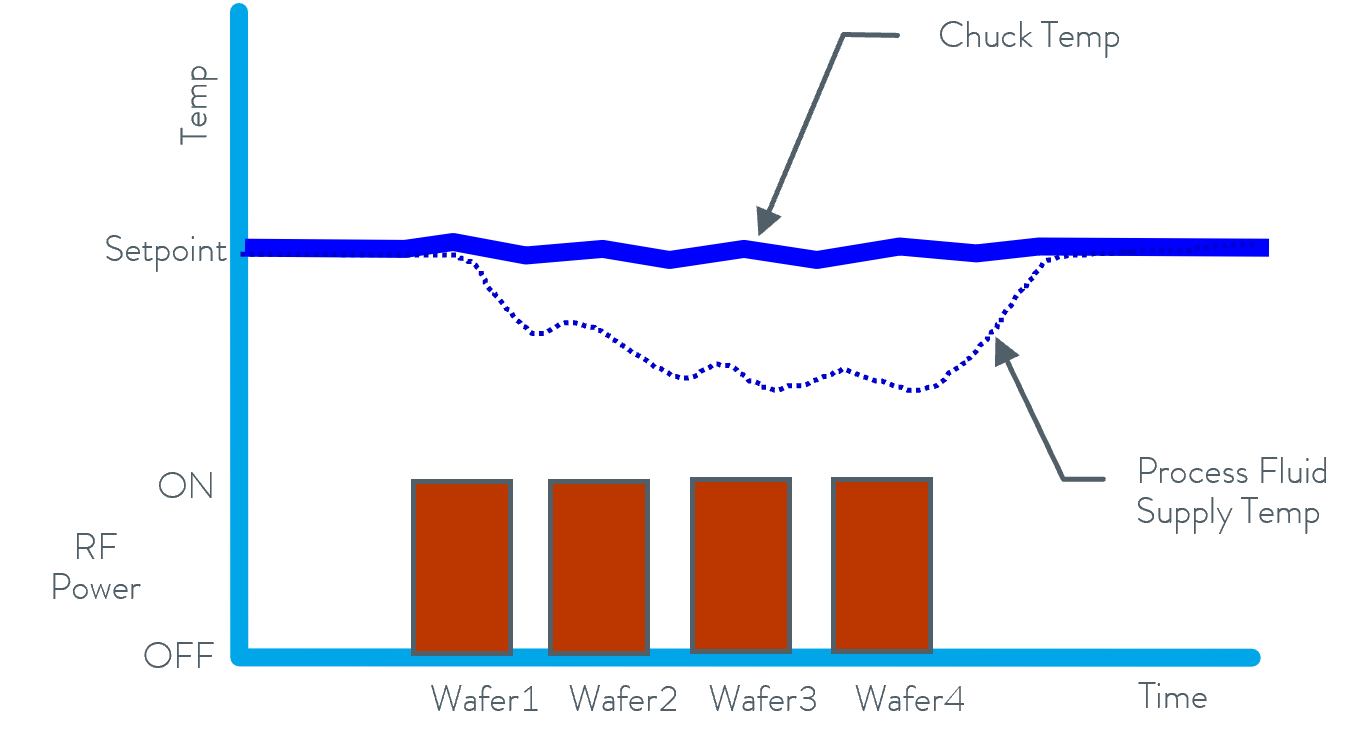

Dynamic Temperature Control

Advantages of Dynamic Temperature Control

- Rapid Temperature Changes: Faster temperature ramp

rates for higher chamber productivity. - Reduced First Wafer Effect: Quicker temperature response

at the start of a lot (can even alleviate the need for a

dummy wafer). - Wafer-to-Wafer Uniformity: Consistent processing

outcomes across all wafers. - Compact Design: Occupies minimal space with sub-floor

installation (nearly zero footprint). - Modular Design: Simplifies troubleshooting and reduces

Mean Time to Repair (MTTR).

Static System

Dynamic System

Semiconductor NEWS & LAUDA BLOG:

Keep up to date with our products, industry news, and informational articles about different processing techniques available to processors.

Thermoelectric Technology in Semiconductor Manufacturing

The semiconductor industry is continuously evolving, with environmental sustainability and space efficiency driving innovation. Among the technologies making significant strides is thermoelectric temperature control—a solid-state solution that combines rapid, precise...

The Critical Role of Temperature Control in Chemical Mechanical Planarization

Chemical Mechanical Planarization (CMP) is a crucial process in semiconductor manufacturing, essential for creating a flat and even surface on semiconductor wafers. Understanding the CMP process and the role of temperature control can significantly enhance the quality...

CASE STUDY: TEL™ Unity IIe SCCM 200mm Temperature Profile Evaluation using LAUDA-Noah DAQ

Process Details Process: Oxide Etch RF Power: 3.6kW (combined upper & lower electrode) Target Temperature (T Set-point): 20 °C at the lower electrode Chiller Comparison: OEM qualified compressor-based chiller vs. LAUDA-Noah POU system Data Acquisition System Setup...