HKS Industrial

Heating and

Cooling

Systems

Made-to-measure installations for industrial applications. Heating, cooling, chilling from -150 up to 550 °C.

Modular Engineering

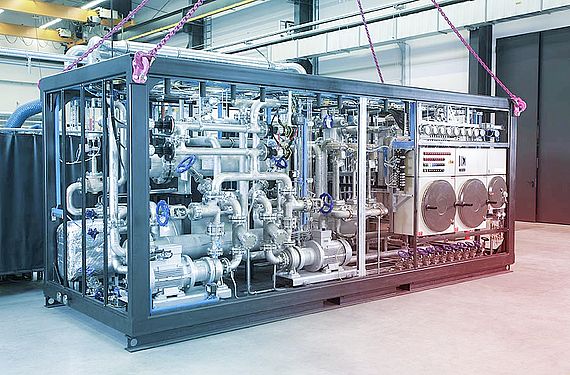

In accordance with the principle of ›modular engineering‹, LAUDA process cooling systems, heat transfer systems and secondary circuit systems are planned and built precisely according to customer‘s wishes: process-oriented, customized and with precision control,meeting the strictest safety standards.

Project engineering is our special field. Working in close co-operation with you we draw up your specific system in the design process. The keyword here is „modular engineering“. Tried and tested modules, combined for the application, provide you with tailor-made solutions. The matching of desired and actual values demands precise planning and exact project work at all interfaces. Each single LAUDA planing module has been proven many times and is continually developed further. This enables us to guarantee our high quality standard.

Download a PDF of our HKS brochure:

LAUDA HKS Brochure (9.5 MB)

Load

Three-way valve

Pump

Electrical heater

Advantages of our Heating and cooling systems

Fundamental component – competent consultation

At LAUDA you deal with specialists right from the start. We know that the right temperature crucially determines the quality of the end product and our advice is specific to your application. Here we can use our wealth of experience from the numerous systems we have produced. Therefore, we spend much time on this step in the procedure. We have broad knowledge of the field and experience in the project management of technologically demanding systems. Competent consultancy is a basic requirement for successful implementation, timely completion and customer satisfaction.

Individual systems – highest quality standard

The best design is nothing without dependable implementation. Our production specialists are experienced and know precisely how special customer requirements are realized in heating and cooling systems. Through the on-going qualification of the staff and the implementation of all the relevant standards, all our systems have one thing in common – high quality with excellent performance data. All material qualities and technical features of components are comprehensively documented and can be traced at any time..

Test run – the system is put through its test

Complete system test in the LAUDA test bench before shipment; system with CE label

- Pressure and leakage test (heat transfer fluid system + cooling system according to AD 2000 guideline)

- Functional test under changing load

- Test of control accuracy

- Test run at max. and min. operating temperatures

- Temperature sensor calibration

- Test of all components relevant to safety in line with EC direct ive

- Test protocol (verification of performance data)

Connecting element – modular engineering

Project engineering is our special field. Working in close co-operation with you we draw up your specific system in the design process. The keyword here is „modular engineering“. Tried and tested modules, combined for the application, provide you with tailor-made solutions. The matching of desired and actual values demands precise planning and exact project work at all interfaces. Each single LAUDA planing module has been proven many times and is continually developed further. This enables us to guarantee our high quality standard.

Optimal interaction – LAUDA plug & play

Since heating and cooling systems consist of ready-to-assemble units, on site they only need to be connected to the consumer. The transport and siting are already taken into account during the planning. Also questions of installation, pipe routing, insulation, safety engineering and explosion protection have to be clarified beforehand. In this respect LAUDA specialists are right up to date and provide competent support.

Dependable service – always available anywhere

LAUDA Heating and cooling systems are designed for continuous operation with very little maintenance. However, international regulations and safety directives demand regular maintenance. To cater for the specific requirements preferably a maintenance plan is drawn up specially for the system. Our experienced service technicians carry out regular servicing. We are supported abroad by qualified representatives. The operating body can rest assured that the system is always properly and verifiably safely maintained when the industrial health and safety directive demands recurring inspections. In special cases our service team is available within 24 hours.