What are Hollow Fiber Perfusion Bioreactors?

Hollow fiber perfusion bioreactors are a specialized class of bioreactors increasingly used in commercial modified protein and monoclonal antibody (mAB) production. These systems pair standard cell culture bioreactors with hollow fiber cartridge filters. The fundamental principle involves using a size exclusion membrane filter to remove target products and cell waste continuously, keeping the culture healthy. Simultaneously, fresh culture media is supplied via a peristaltic pump. There are other types of perfusion reactors, such as wave reactors and spinning cell reactors, but for today we’re going to be focused on single-use bioreactor systems.

Advantages of Hollow Fiber Perfusion Systems

These perfusion systems significantly enhance the yields of recombinant proteins and mABs. Specialized cell lines optimized for these conditions are employed in standard bioreactors. Once optimal cell density and conditions are achieved, triggers initiate the expression of the target protein or antibody. Unlike traditional batch-style cell culture, perfusion reactors can operate continuously for extended periods, with some systems running for up to six months (I. Jyothilekshmi and N. S. Jayaprakash, 2020). During this process, products are filtered out through hollow fiber cartridges, producing a crude antibody mixture that is then purified through chromatography, typically using affinity and ion-exchange methods.

The Role of Temperature in Perfusion

Temperature, along with pH and chemical conditions, is critical in triggering and maintaining the expression of the target protein or mAB. Optimized cell lines are designed to perform under ideal conditions, which must be kept stable throughout the process. Once the conditions stray from the parameters by a pre-determined amount, the run is concluded.

This is where LAUDA excels. Known for precision temperature control, LAUDA is the preferred choice for many major bioreactor manufacturers. Our systems offer tight temperature tolerances, high power where needed, and innovative features designed with cGMP compliance, technician convenience, and environmental considerations in mind. The LAUDA Variocool NRTL units are particularly effective for cell culture temperature control, making them an essential component for maintaining optimal conditions in perfusion bioreactors.

Advantages Over Traditional Cell Culture

Perfusion bioreactors offer higher yields, lower costs, and can often be integrated into existing infrastructure with minimal modifications. Since the reactors and filters are standard in biotech labs, these systems are easy to construct, operate, and customize. However, the initial cost of re-tooling and the need for compatible cell lines may pose challenges.

Impact on Consumers

The benefits of perfusion bioreactors extend to consumers by reducing the cost of expensive medicines. High costs associated with consumables, salaries, and research often translate into high prices for end-users. As the industry moves toward personalized therapies, reducing production costs is crucial. On a personal note, my mother is currently using a mAB medicine (Humira/adalimumab). Monoclonal antibodies are becoming increasingly common and can be very expensive.

In the US, single doses of mABs can be in the thousands. Examples include:

• Dupixent (dupilumab; asthma, eczema) – average retail price $7,004.89

• Adakevo (crizanlizumab; sickle cell related pain) – average retail price $7,910.01

• Briumvi (ublituximab; MS) – average retail price $42,667.96

• Bamlanivimab/etesevimab (Bamlanivimab/etesevimab; emergency use Covid-19) – average retail price $3.00.

Lowering production costs through efficient bioreactor systems can make these vital medicines more accessible.

Conclusion

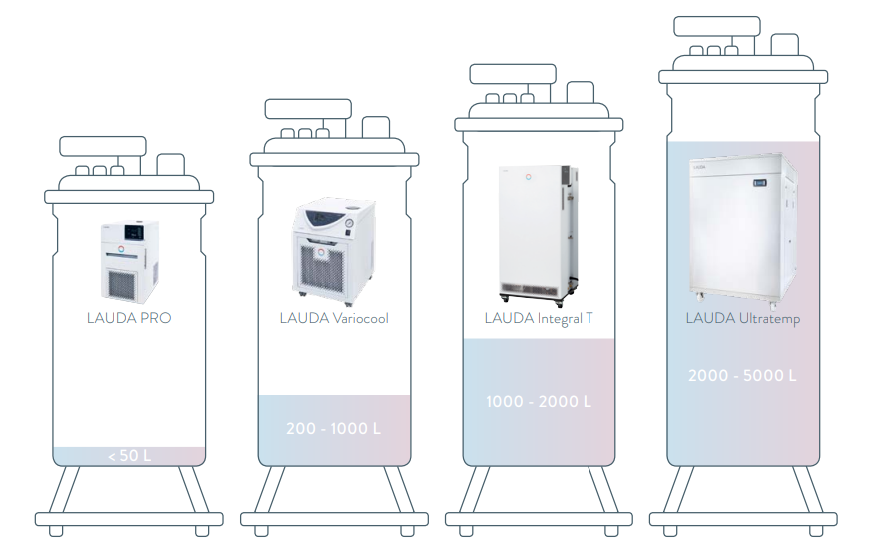

Recombinant proteins and mABs are valuable biomedicines, and reducing their production costs holds significant life-saving potential. Perfusion bioreactors, as opposed to batch-style systems, offer a promising path to bringing new, affordable medicines to market while consuming fewer resources. LAUDA continues to innovate, providing advanced temperature control solutions to support the evolving biologics economy. Our Ultratemp line, capable of supporting heating and cooling for volumes up to 5000 liters (50 kW heating & cooling, -5 to +60°C), is available now to meet the demands of large-scale perfusion bioreactors.

This post was authored by Christopher Sebastiano, Southeast Sales Manager at LAUDA.