In the realm of semiconductor manufacturing, precision and efficiency are critical. Temperature control within process chambers, especially the wafer chuck, is pivotal for consistent semiconductor fabrication. This post compares Dynamic Temperature Control and Static Heating & Cooling Units, exploring their functions and advantages in depth.

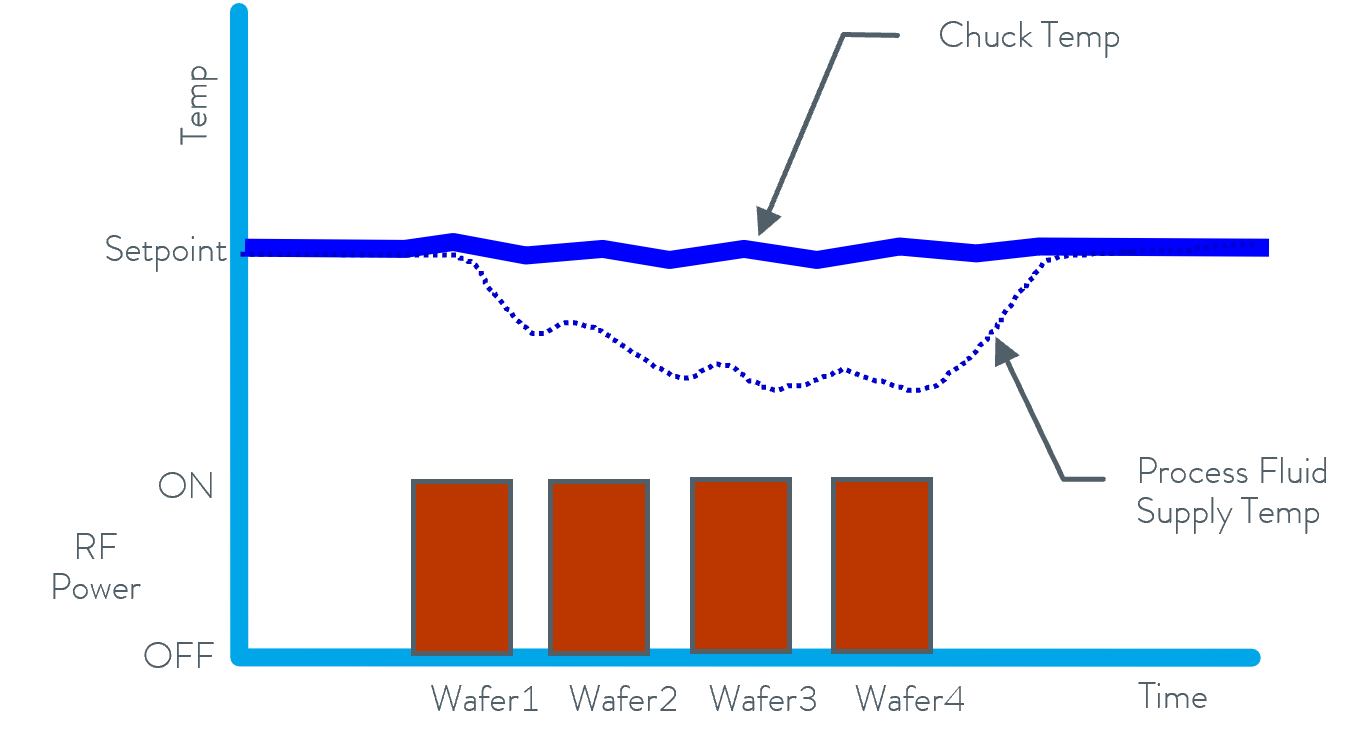

Dynamic Temperature Control: Real-time Adaptation for Enhanced Uniformity

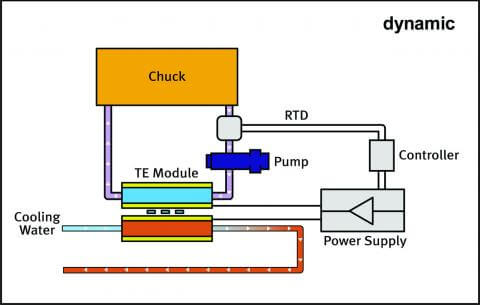

Dynamic Temperature Control, as implemented in systems like the LAUDA-Noah POU, is an approach that senses the temperature of the process fluid returning from the process chamber’s wafer chuck (ESC) and dynamically adjusts the temperature of the supplied process fluid based on this real-time feedback. With our unit strategically mounted approximately six feet from the chamber, we achieve a much more accurate reading of the chuck temperature. This approach ensures consistent temperature throughout the production lot, leading to improved wafer-to-wafer CD uniformity.

The key technical advantages of Dynamic Temperature Control are as follows:

- Rapid Temperature Changes: Faster temperature ramp rates, resulting in higher chamber productivity.

- Reduced First Wafer Effect: Quicker temperature response at the beginning of a lot, potentially eliminating the need for a dummy wafer.

- Wafer-to-Wafer Uniformity: Consistent processing outcomes across all wafers.

- Compact Design: Occupies minimal space with sub-floor installation (nearly zero footprint).

- Modular Design: Simplifies troubleshooting and reduces Mean Time to Repair (MTTR), ensuring minimal downtime.

Dynamic System

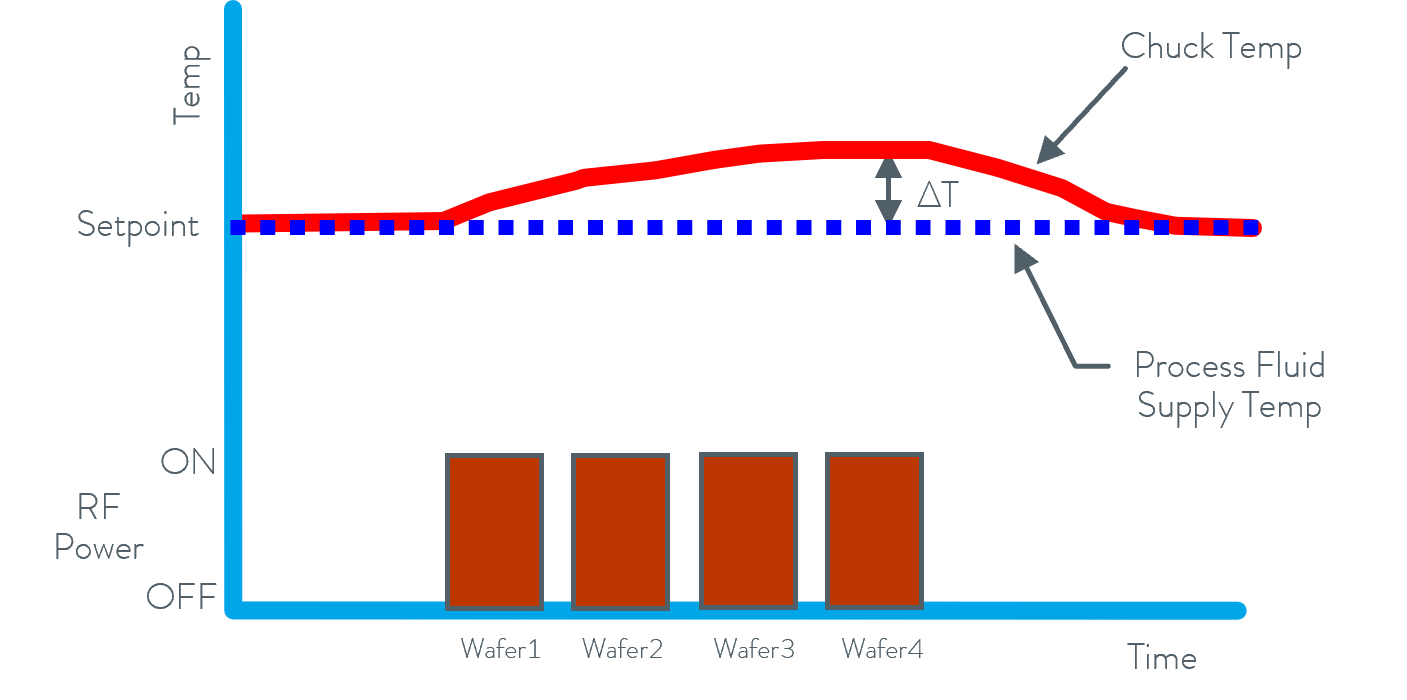

Static Heating & Cooling Units: Inefficiency and Limited Control

In contrast to Dynamic Temperature Control, Static Heating & Cooling Units rely on maintaining the temperature set-point in a large reservoir by cycling heaters and cooling control valves on and off. This approach has several technical drawbacks:

- Large Footprint: Static units occupy significant space within the fabrication tool area, reducing its efficiency.

- High Fluid Consumption: These units require around six times more process fluid compared to Dynamic POU systems.

- Remote Locations: Static units are typically situated remotely, increasing cost and decreasing overall system efficiency.

- Compressor and Pump Maintenance: The presence of compressors and large pumps necessitates frequent maintenance and consumes approximately 50% more power than Dynamic POU systems.

Static System

A Real-World Comparison: The Data Speaks

To illustrate the technical benefits of Dynamic Temperature Control over Static Heating & Cooling Units, we present data from an Asia Pacific wafer foundry. The data pertains to a 300mm chamber temperature profile during a high aspect ratio Etch process, operating at very high RF power conditions (~3.8kW). The compelling aspects of this data set are:

- Temperature Uniformity: The LAUDA-Noah POU system consistently maintains temperature uniformity, while static units show variations.

- Rapid Response Times: The LAUDA-Noah POU system exhibits swift response times, ensuring stable wafer processing under dynamic conditions.

- Wafer-to-Wafer Repeatability: Consistency in temperature control results in high wafer-to-wafer repeatability.

- Constant Baseline Temperature: The baseline temperature performance of the Dynamic POU system remains stable throughout the process.

In conclusion, Dynamic Temperature Control, exemplified by the LAUDA-Noah POU system, is a technically superior method for precise and uniform temperature control within semiconductor process chambers. Its real-time adaptation, efficiency, and reliability, along with advantages like rapid temperature changes and wafer uniformity, elevate semiconductor manufacturing to meet the industry’s stringent standards.