Ultratemp

Process

Thermostats

High-performance temperature control for biotechnology and pharmaceutical engineering

- Process thermostat with integrated heater

- Integrated Ethernet interface / Operation possible via web server

- Available connection for external Pt100 sensor

- Stainless steel housing

- Fully electronic continuous controller with PID action

- Industrial block pump with high pressure and high flow rate

- Operates with non flammable liquids (water,water/glycol)

- Condenser cooling water

Application examples:

- Bioreactor Temperature Control

- Pharmaceutical Manufacturing

- Chemical Synthesis

- Food and Beverage Processing

- Environmental Testing

- Material Testing

- Energy Storage Testing

- Automotive Testing

Download a PDF of our Ultratem brochure:

LAUDA Ultratemp Brochure (1.3 MB)

Working temperature min.

-5 °C

Working temperature max.

60 °C

Robust and easy to clean

Easy operation and remote monitoring

Intuitive operation is provided directly at the device via function buttons and an LCD. Furthermore, the unit can be controlled via PC with an integrated web server. The unit is prepared for the cloud-based digital applications from LAUDA. These offer intelligent analysis and monitoring tools, as well as remote maintenance functions that maximize the operating time, reliability and performance of all LAUDA devices.

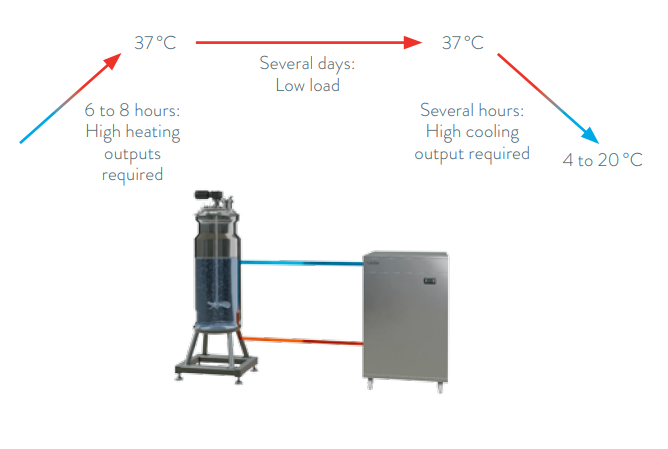

Powerful and dynamic

Typical biotech and industrial applications for the new LAUDA Ultratemp process thermostats require high heating and cooling output within a moderate temperature range. High external volumes can be quickly heated up and cooled down again with outputs from 25 to 50 kW.

Application-optimized equipment

LAUDA Ultratemp process thermostats enable exact regulation to an external temperature within a range of −5 to 60°C. Their high temperature stability of ±0.5 K guarantees a precise temperature in the application. The water-cooled design minimizes the heat emitted to the environment. Use with non-flammable liquids (water or water-glycol) provides easy handling and low operating costs.

Worldwide operation

The devices are available with a 400 V; 3/PE; 50 Hz & 460 V; 3/PE; 60 Hz bi-frequency power supply and can therefore be used worldwide. There is also a unit with 400 V; 3/PE; 50 Hz, which has been optimized for a mains frequency of 50 Hz. All variants can be operated within an ambient temperature range of −15 to 50°C

Ultratemp Process Thermostats

| Technical features | UT 2505 W | UT 3505 W | UT 5005 W |

| Select to compare: | |||

| Working temperature min. °C | -5 | -5 | -5 | Working temperature max. °C | 60 | 60 | 60 | Ambient temperature min. °C | -15 | -15 | -15 | Ambient temperature max. °C | 50 | 50 | 50 | Temperature stability ±K | 0.5 | 0.5 | 0.5 | Heater power max. kW | 35 | 35 | 50 | Cooling output at 20 °C kW | 30.3 | 41.1 | 55.6 | Pump flow nominal L/min | 90 | 90 | 180 | Cat. No. 400 V; 3/PE; 50 Hz & 460 V; 3/PE; 60 Hz | L004023 | L004025 | L004027 |

|

Summary

|

Summary

|

Summary

|

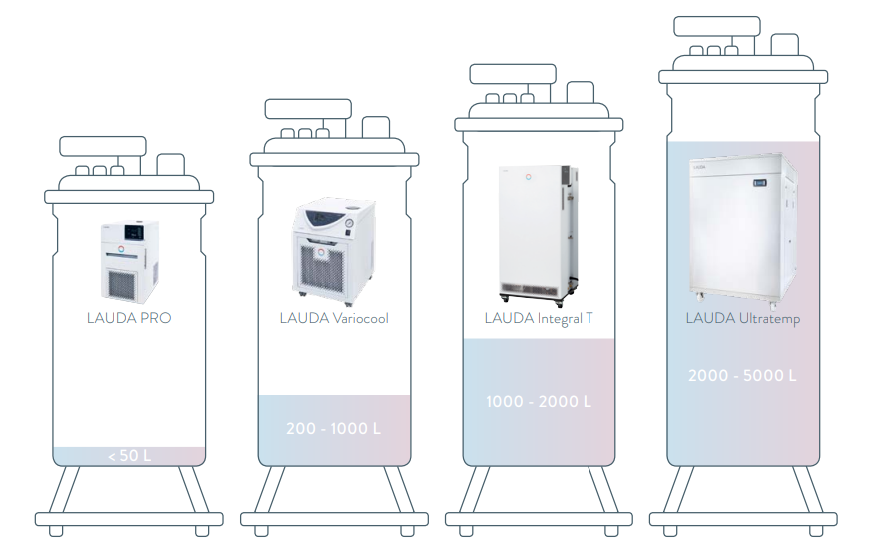

Areas of Application

LAUDA offers temperature control solutions in all the requisite performance classes for applications in the biopharmaceutical industry and for biotechnical processes, e.g. in the novel food sector. Microcool circulation chillers and PRO process thermostats are available for laboratory reactors.The temperature of reactors with 200 to 2000 liters can be controlled with process thermostats from the Variocool and Integral line. The new Ultratemp line means that LAUDA can now offer solutions for reactors and mixers with a volume of up to 5000 liters.