Hydrogen has a key role to play in managing the energy transition. Hydrogen is extremely important for an environmentally friendly energy system, both for energy storage to supply heat and for future mobility. But this element has its downsides. Powerful cooling devices are needed to handle it. As the global market leader for temperature control technology, LAUDA already offers the relevant technology for electrolyzers and hydrogen fueling. As part of Horizon Europe, the new EU research project RHeaDHy is expanding this expertise even further with the development of innovative and powerful solutions for faster refueling in heavy-duty applications.

4 million euros for European hydrogen development – LAUDA is setting new standards

Launched on February 1, 2023, the innovation project RHeaDHy aims to advance the development of high-performance hydrogen fueling stations. To this end, the European Union will contribute almost 4 million euros in funding to the project. The ultimate goal is to reduce carbon dioxide emissions from freight transport using hydrogen-powered vehicles. However, in order for the solution to be viable, it must be possible to refuel trucks and other means of transport of a similar size within a short time – the target for refueling a truck with 100 kg of hydrogen is ten minutes. In order to do this, the hydrogen must be refueled under high pressure, which significantly increases the temperature. As a member of a consortium consisting of several European partners, LAUDA will be responsible for the development of a high-performance cooling system. LAUDA will also set standards for the future while helping to develop new standards for hydrogen refueling. The project is scheduled to run until early 2027. By the end of the project, near-series technology should be available and installed at two locations: one refueling station will be opened in Germany and another in France.

Refrigeration technology for the hydrogen industry ready for series production

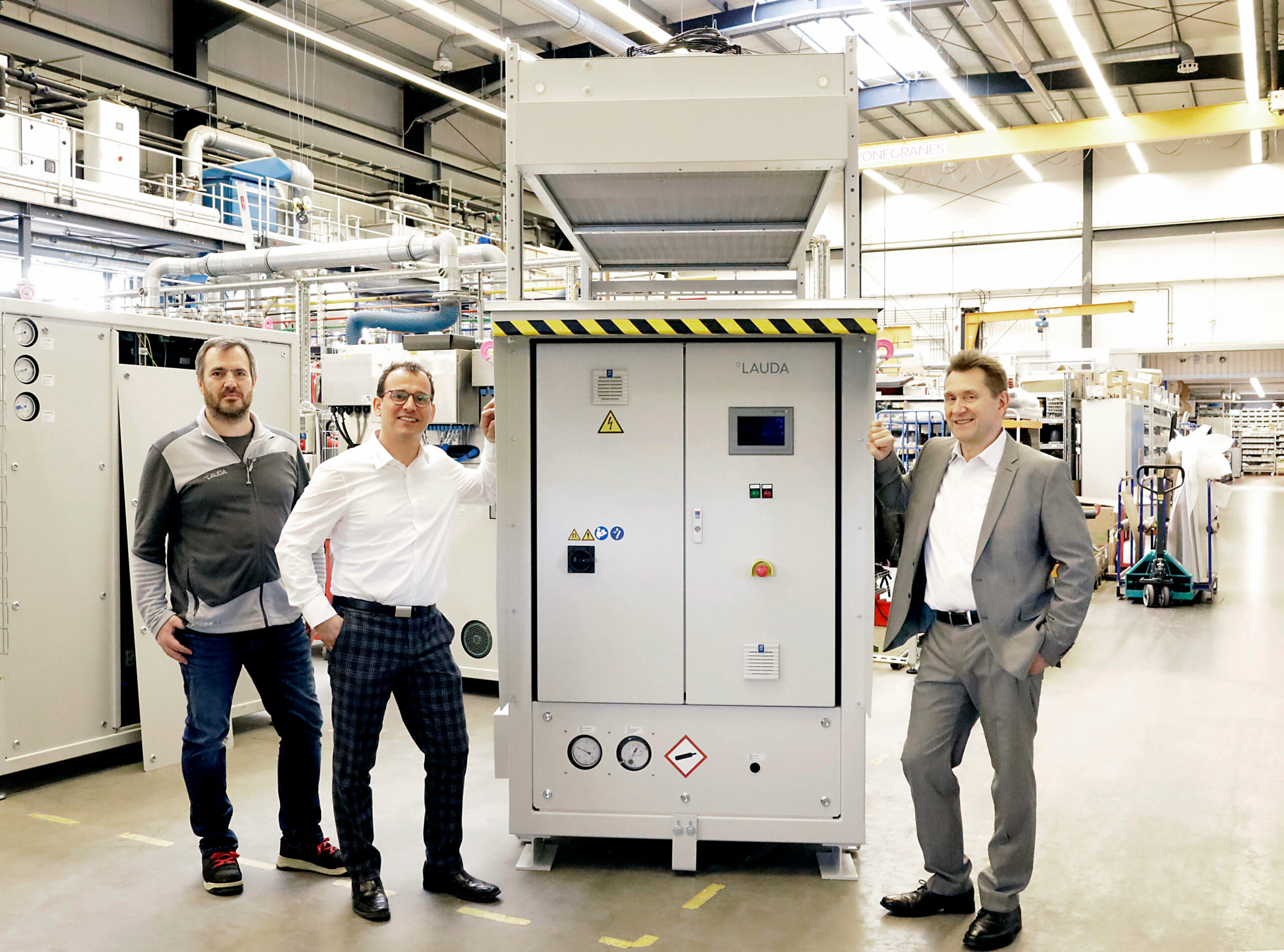

LAUDA has been a strong partner to producers and operators of hydrogen refueling stations since 2015, and in this time, has delivered dozens of systems to various industry leaders. These systems include SUK 350 L process cooling units for cooling hydrogen during refueling, as well as Ultracool line circulation chillers for cooling the electrolyzers during hydrogen production, both of which are serially produced.

In view of the strong market growth in the hydrogen industry and the forecast of around 3,000 additional hydrogen refueling stations by 2030 in Europe alone, LAUDA is preparing to significantly expand its production capacities for SUK units. The Ultracool series has already been prepared for the increase in demand: firstly, investments of around 7 million euros have allowed the multiplication of production capacities. Secondly, work on redeveloping the product line began as early as 2019 to make it more compact, more powerful and more energy-efficient. Several new models will be launched later this year to meet the growing demand for even more powerful units. LAUDA can cover cooling capacities of up to 240 kW with the serially produced Ultracool product line.

The temperature control specialists from LAUDA have committed themselves to provide outstanding performance for a better future (Empowering Excellence. For a better future). Once again, they have shown their willingness to break new ground and devote themselves to pioneering technologies. With the EU research project, LAUDA is also underscoring its expertise in the field of hydrogen cooling and its will to continuously promote innovation and development.