Integral T/XT

New Generation

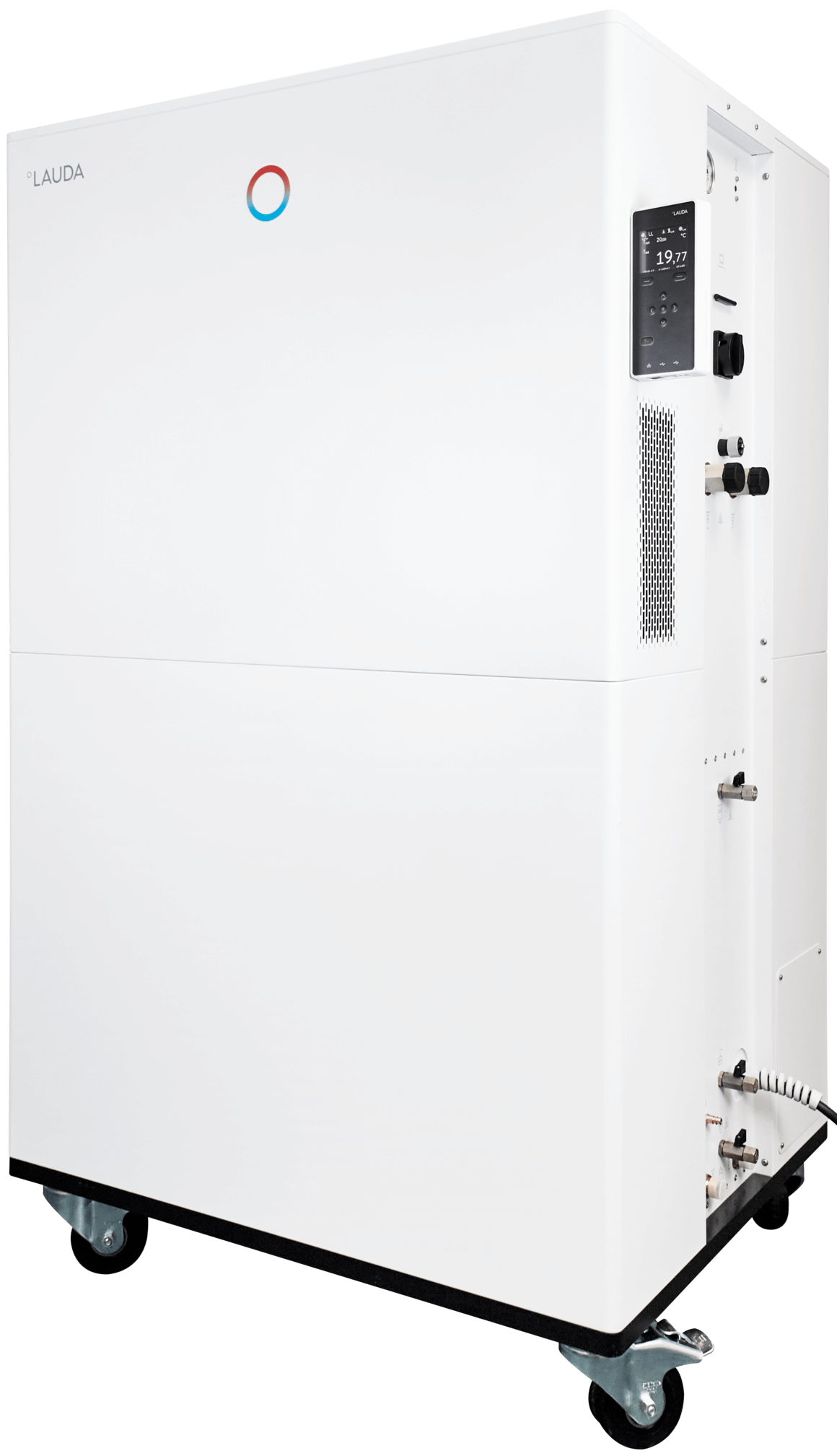

The new generation of LAUDA Integral T process thermostats for professional external temperature control processes from -30 to 150 °C.

The new generation of successful Integral XT process thermostats for professional temperature control in the temperature range from -90 to 320 °C

The new Integral T units enable rapid temperature changes due to adapted heating and cooling capacities with small internal volumes. Due to the open hydraulic system, the unit vents quickly and without functional restrictions. This makes it ideal for temperature control processes with frequent consumer or specimen changes. A reliable, powerful submersible pump and the internal bypass for pressure limitation are standard features of the Integral T. The modular interface concept is now also implemented in the Integral T and ensures maximum networking of the user processes.

The powerful Integral XT process thermostats use the flow principle with cold oil superimposition. It allows users to use a wide temperature range with a temperature control medium. The electronically controlled, magnetically coupled eight-stage LAUDA Variopump allows the optimum thermal connection of the volume flow both for pressure-sensitive consumers and for applications with high hydraulic resistance. The modular interface concept ensures maximum networking of the user processes.

Aerospace Applications

- Simulation of space conditions

- Life cycle testing

- Functional testing of electronic units

Automotive Applications

- Battery testing

- Performance test in fuel cell technology

- Test stands for combustion engines

Chemical and Pharmaceutical Applications

- Control of microreaction syntheses

- Cryogenic processing or organometallic couplings

Bioproduction Applications

- Constant temperature control of single-use bioreactor

- Quenching of reaction processes

- Control of scale-up processes

![]()

Working temperature min.

-90 °C

![]()

Working temperature max.

320 °C

Download a PDF of our Integral brochure:

LAUDA Integral Brochure (3.1 MB)

Operation directly on the device

Operation via Command touch remote control

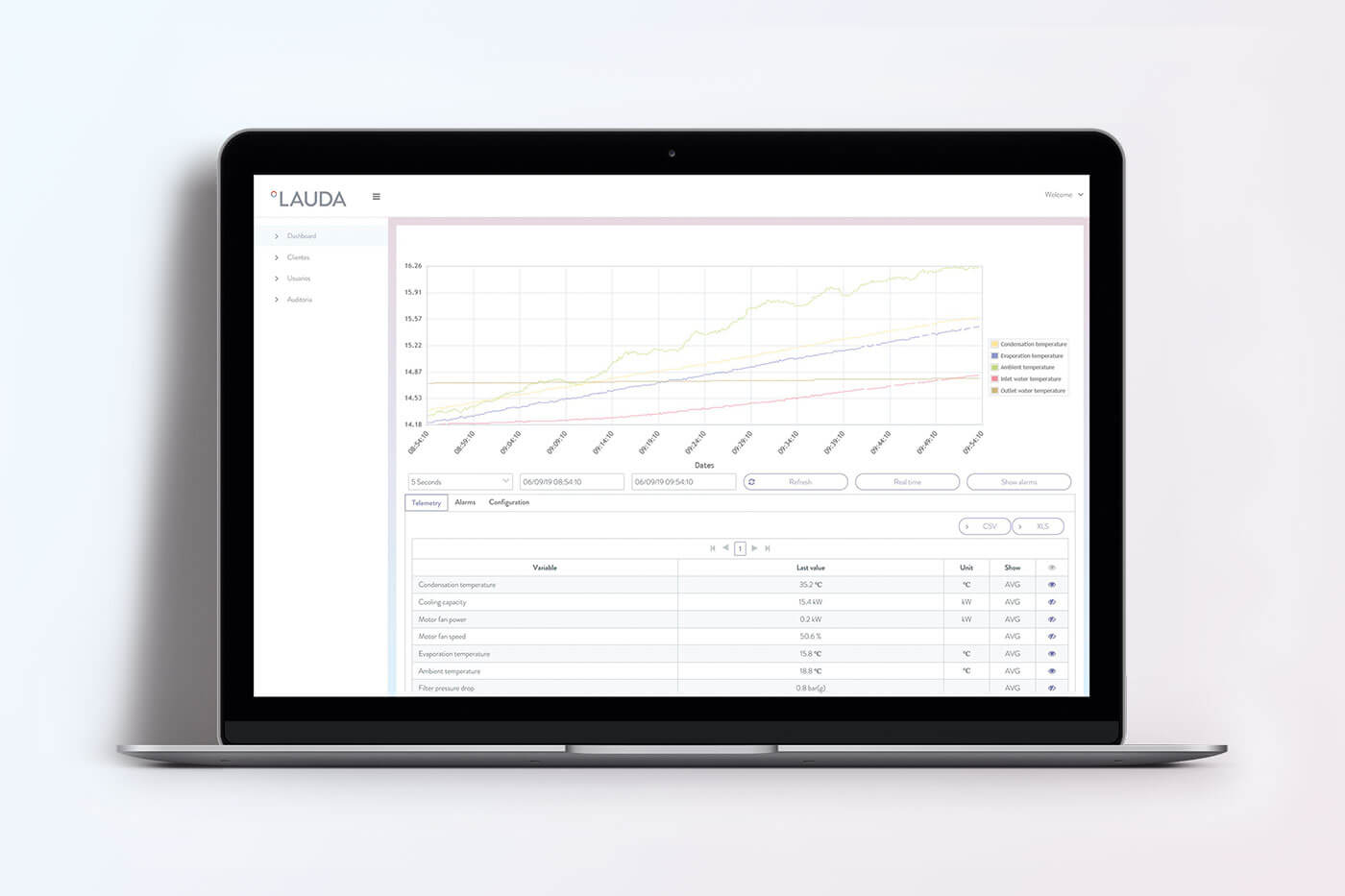

New Connectivity features on the LAUDA Cloud

Increased heating and cooling capacities

Automatic self adaptation determines ideal control parameters for your application

Simple liquids management information are stored in the integrated heat transfer liquid database

High precision through-flow control

Efficient SmartCool system regulates the cooling capacity ensuring efficient, dynamic temperature control

LAUDA Integral T

Equipment

- Compact open bath system

- Powerful immersion pressure pump

- Adjustable bypass for pressure limitation

- Independent internal circulation

Benefits

- Fast aeration and outgassing

- High output and working pressures

- Preventive protection for pressure-sensitive consumers

- The function of the device is guaranteed if the flow to the consumer is interrupted

LAUDA Integral XT

Equipment

- Flow system with a low active volume

- Hydraulic system with a cold oil blanket

- Powerful magnetically coupled Vario pump

- Adjustable bypass for internal through-flow control

Benefits

- Fast aeration and outgassing

- Larger temperature range and longer service life of the temperature control media

- Preventive protection for pressure-sensitive consumers provided by an eight-stage Vario pump

- Optimum performance of the XT even at extremely high pressure drops with low flow rates

LAUDA Integral P

LAUDA Integral P process thermostats operate on the principle of pressure superposition. The devices, equipped with a stainless steel pressure vessel, significantly extend the temperature range of non-flammable heat transfer media. Thus, the new Integral P process thermostats enable, for example, the testing of drive systems or stress tests under realistic conditions at favorable operating costs. Integral P process thermostats operate in the working temperature range from -40 to 140 °C with a cooling capacity of 20 or 25 kW when testing with water/glycol

Equipment

- Flow system with a low active volume

- Hydraulic system with pressure overlay

- Powerful magnetically coupled pump

- Adjustable bypass for internal through-flow control

- Venturi element for vacuum filing

Benefits

- Quick heating and cooling cycles

- Expanded temperature range for water/glycol applications

- Demand-based flow rates in the application

- Optimal performance of the Integral P even with a high pressure drop in the application

- Simple handling of the consumer’s heat transfer liquid

Integral IN T

| Technical features | IN 130 T | IN 230 T | IN 230 TW | IN 530 T | IN 530 TW | IN 1030 T | IN 1330 TW | IN 1830 TW |

| Select to compare: | ||||||||

| Working temperature min. °C | -30 | -30 | -30 | -30 | -30 | -30 | -30 | -30 | Working temperature max. °C | 120 | 120 | 120 | 120 | 120 | 150 | 150 | 150 | Filling Volume min. L | 3.6 | 3.6 | 3.6 | 7.2 | 7.2 | 9.7 | 9.7 | 9.7 | Filling Volume max. L | 8.7 | 8.7 | 8.7 | 20.5 | 20.5 | 25.5 | 25.5 | 25.5 | Heater power max. kW | 2.7 | 2.7 | 2.7 | 8 | 8 | 8 | 16 | 16 | Cooling output at 20 °C kW | 1.4 | 2.2 | 2.3 | 5 | 6 | 11 | 13 | 19 | Temperature stability ±K | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.1 | 0.1 | 0.1 | Pump pressure max. bar | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 5.5 | 5.5 | 5.5 | Pump flow max. L/min | 40 | 40 | 40 | 40 | 40 | 60 | 60 | 60 | Cat. No. 208-220 V; 60 Hz | L002788 | L002791 | L002792 | Cat. No. 400 V; 3/PE; 50 Hz & 460 V; 3/PE; 60 Hz | L002883 | L002884 | L002885 | L002886 | L003274 |

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Integral IN XT

| Technical features | IN 150 XT | IN 550 XT | IN 550 XTW | IN 750 XT | IN 250 XTW | IN 950 XTW | IN 280 XT | IN 280 XTW | IN 1590 XTW | IN 590 XTW | IN 1850 XTW | IN 2560 XTW |

| Select to compare: | ||||||||||||

| Working temperature min. °C | -45 | -50 | -50 | -45 | -45 | -50 | -80 | -80 | -90 | -90 | -50 | -60 | Working temperature max. °C | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | Filling Volume min. L | 2.5 | 4.8 | 4.8 | 4.8 | 2.5 | 4.8 | 4.8 | 4.8 | 10 | 8 | 8 | 12.6 | Filling Volume max. L | 8.7 | 17.2 | 17.2 | 17.2 | 8.7 | 17.2 | 17.2 | 17.2 | 30.6 | 28.6 | 28.6 | 34.4 | Heater power max. kW | 3.5 | 8 | 8 | 8 | 3.5 | 8 | 4 | 4 | 12 | 8 | 16 | 24 | Cooling output at 20 °C kW | 1.5 | 5 | 5.8 | 7 | 2.1 | 9.5 | 1.6 | 1.7 | 18.5 | 4.5 | 20 | 25 | Temperature stability ±K | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.1 | Pump pressure max. bar | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 6 | 6 | Pump flow max. L/min | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 120 | 100 | Cat. No. 208-220 V; 60 Hz | L002794 | L002796 | Cat. No. 400 V; 3/PE; 50 Hz & 460 V; 3/PE; 60 Hz | L002887 | L002888 | L002889 | L002890 | L002892 | L002893 | L002898 | L002897 | L002895 | L002681 |

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Summary

|

Integral IN P

| Technical features | IN 2050 PW | IN 2560 PW |

| Select to compare: | ||

| Working temperature min. °C | -40 | -40 | Working temperature max. °C | 140 | 140 | Filling Volume min. L | 11.1 | 12.1 | Filling Volume max. L | 36.3 | 48.1 | Heater power max. kW | 16 | 24 | Cooling output at 20 °C kW | 20 | 25 | Temperature stability ±K | 0.05 | 0.1 | Pump pressure max. bar | 6 | 6 | Pump flow max. L/min | 120 | 100 | Cat. No. 400 V; 3/PE; 50 Hz & 460 V; 3/PE; 60 Hz | L003319 | L003308 |

|

Summary

|

Summary

|

| Technical features | IN 4 XTW | IN 8 XTW |

| Select to compare: | ||

| Working temperature min. °C | 25 | 25 | Working temperature max. °C | 320 | 320 | Filling Volume min. L | 3.3 | 3.6 | Filling Volume max. L | 9.5 | 9.8 | Heater power max. kW | 3.3 | 8 | Cooling output at 100 °C kW | 10 | 10 | Temperature stability ±K | 0.1 | 0.1 | Pump pressure max. bar | 3.1 | 3.1 | Pump flow max. L/min | 60 | 60 | Cat. No. 208-220 V; 60 Hz | L002800 | Cat. No. 400 V; 3/PE; 50 Hz & 460 V; 3/PE; 60 Hz | L002891 |

|

Summary

|

Summary

|

Flow control

LAUDA offers an optional through-flow control unit for the new Integral XT models which is indispensable for high reproducibility, especially when creating volume flow-dependent test processes. The through-flow control unit guarantees a defined flow rate from the thermostat to the consumer. The intelligent control system allows the defined flow rate to be kept constant, even if the viscosity, temperature or specimen change.

| Cat. No. | Designation | Description |

| L002775 | LAUDA Integral XT l through-flow controller 230 V; 50 Hz |

Permissible temperature control medium water/glycol mixture. Working temperature range −30 °C … 80 °C Through-flow control range 0.2 … 20 L/min |

| L003217 | LAUDA flow control MID 80 LiBus, compatible with Integral IN XT, IN P |

Flow control system with magnetic inductive measurement principle Premitted heat transfer liquids: water/glycol mixtures User-interface allows setting and control of the temperature control unit Working temperature range −40 °C … 140 °C Through-flow control range 0.2 … 70 L/min |

| LSOZ0014 | Hose set M30 × 1.5 I to M30 × 1.5 | 1.9 m long / insulation 19 mm |

| LSOZ0015 | Hose set M38 × 1.5 I to M30 × 1.5 | 1.9 m long / insulation 19 mm |

Metal hoses

| Cat. No. | Description | Length/cm | di | da | Temp. Range | Insulation |

| LZM 091 | Metal hose M30 × 1.5 I-M30 × 1.5 I | 100 | 20 | 76 | −100 … 350 | Multi-layered |

| LZM 092 | Metal hose M30 × 1.5 I-M30 × 1.5 I | 200 | 20 | 76 | −100 … 350 | Multi-layered |

| LZM 093 | Metal hose M30 × 1.5 I-M30 × 1.5 I | 300 | 20 | 76 | −100 … 350 | Multi-layered |

| LZM 087 | Metal hose M30 × 1.5 I-M30 × 1.5 I | 100 | 20 | 76 | −90 … 150 | Single-layered |

| LZM 088 | Metal hose M30 × 1.5 I-M30 × 1.5 I | 200 | 20 | 76 | −90 … 150 | Single-layered |

| LZM 089 | Metal hose M30 × 1.5 I-M30 × 1.5 I | 300 | 20 | 76 | −90 … 150 | Single-layered |

| LZM 094 | Metal hose M38 × 1.5 I-M38 × 1.5 I | 100 | 25 | 78 | −100 … 350 | Multi-layered |

| LZM 095 | Metal hose M38 × 1.5 I-M38 × 1.5 I | 200 | 25 | 78 | −100 … 350 | Multi-layered |

| LZM 096 | Metal hose M38 × 1.5 I-M38 × 1.5 I | 300 | 25 | 78 | −100 … 350 | Multi-layered |

| LZM 075 | Metal hose G 3/4 I-G 3/4 I | 100 | 20 | 51 | −50 … 150 | Single-layered |

| LZM 076 | Metal hose G 3/4 I-G 3/4 I | 200 | 20 | 51 | −50 … 150 | Single-layered |

Adapter M30 x 1.5

| Cat. No. | Designation | Description |

| HKA 161 | Nipple | 1/2 in nipple with ball bush |

| HKA 162 | Nipple | 3/4 in nipple with ball bush |

| EOV 196 | Screw Cap | M30× 1,5 I |

| HKA 152 | Adapter | M30× 1.5 A – M16× 1 I |

| HKA 170 | Adapter | M30× 1.5 I – G ¾ A |

| HKA 172 | Adapter | M30× 1,5 I – NPT¾ A |

| HKA 156 | Flange Adapter | M30× 1.5 A – Flange DN25×33.7mm |

| HKA 153 | Elbow coupling | M30× 1.5 I – M30× 1.5 A |

| EOV 208 | Double nipple | 2×M30× 1.5 A – M30× 1.5 A |

| UD 660 | Reducer | M30× 1.5 I – M16× 1 A |

| HKN 232 | Threaded Connection for welding on |

M30× 1.5 A – ID=22.3/AD=26.9 mm |

| EOV 194 | Screw-in stud | M30× 1.5 A – G¾ A |

| EOV 206 | Screw-in stud | M30× 1.5 A – G1 A |

| EOV 207 | Screw-in stud | M30× 1.5 A – NPT¾ A |

| EOV 204 | Ball Bush | ID=22.2/AD=24 mm |

| HKN 248 | Threaded connection | M30× 1.5 A – ID=10.2/AD=12.7 mm |

Adapter M38 x 1.5

| Cat. No. | Designation | Description |

| HKA 168 | Nipple | 1 in. nipple with ball bush |

| EOV 197 | Screw cap | M38× 1,5 I |

| UD 663 | Reducer | M38× 1.5 I – M30× 1.5A |

| EOV 195 | Screw-in stud | M38× 1.5 -G1 in. |

| EOV 223 | Screw-in stud | M38× 1.5- G1¼ in. |

| EOV 224 | Screw-in stud | M38× 1.5- NPT1 in. |

| HKA 198 | Flange adapter | M38× 1.5 A – Flange DN25×33.7 mm |

| HKA 165 | Elbow coupling | M38× 1.5 I – M38× 1.5 A |

Ball cocks

| Cat. No. | Designation | Description |

| LWZ 073 | Ball cock −30 … 180°C | M30× 1.5 I – M30× 1.5 A |

| LWZ 074 | Ball cock −30 … 180°C | M38× 1.5 I – M38× 1.5 A |

| LWZ 134 | Ball cock −20 … 150°C | G¾ I – G¾ A |