Our Process Chillers Are Always Ultracool

We’ve taken ULTRACOOL to a whole new level

Upgrade to a new ULTRACOOL chiller for:

- Energy savings: up to 50%

- State-of-the-art connectivity: LCD remote control, computer/LAN integration, Cloud storage and data exchange

- Increased temperature stability: ±0.5 K

- Space savings: nearly 40% smaller than previous generation

- Reduced water tank volumes: up to 80% smaller, easing installation and maintenance cost

Applications include:

Digital printing

Laser cutting

Laser sorting

Point welding

Induction heating

Injection molding

And more!

TALK TO A LAUDA TECHNICAL EXPERT

Schedule a 1:1 discussion about your process requirements with a LAUDA expert today.

Take advantage of our Extended Warranty Program!

Now is the time to upgrade to the next generation of LAUDA Ultracool chillers. For a limited time, get an additional 6-month extended warranty when you purchase the optional 12-month extended warranty. Ask your LAUDA-Brinkmann representative for details.

At LAUDA, we’re focused on continual improvement – and here’s how we’ve improved our ULTRACOOL chillers for your:

| ULTRACOOL New Generation |

ULTRACOOL Original |

|

| Temperature range | -10 °C…35 °C | -5 °C…25 °C |

| Temperature stability | +/-0.5 K | +/-2 K |

| Footprint | Up to 40% Smaller | Dependent on model |

| Remote control panel | Standard | Optional |

| Speed regulation | Standard | Optional |

| Preheating (by pump) | Standard | Optional |

| Bifrequent power supply | Standard | Optional |

| °C to °F selection | Standard | Optional |

| Integrated Ethernet | Standard | Not Available |

| Variable speed pump | Option | Not Available |

| Cloud connection | Accessory | Not Available |

Download a PDF of our Ultracool brochure:

LAUDA Ultracool Industrial Chillers Brochure (1.7 MB)

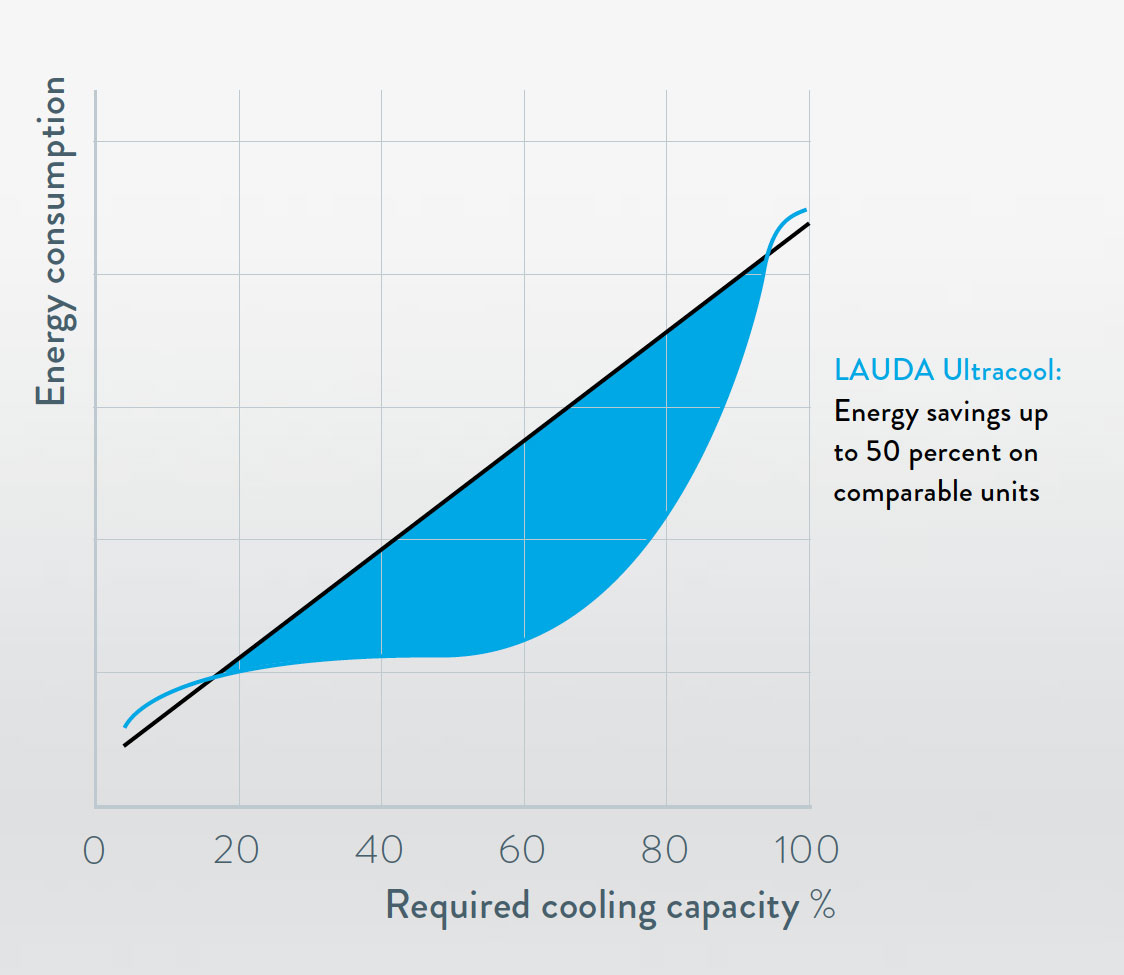

Energy efficient

Savings up to 50% (compared to conventional chillers)

The new LAUDA Ultracool line increases energy efficiency and reduces operating costs. All models comply with the Ecodesign Directive 2009/125/EC, which defines energy efficiency values (SEPR) for process circulation chillers. Depending on operating conditions, these models reduce energy costs by up to 50 percent compared to conventional chillers that are not Ecodesign-compliant.

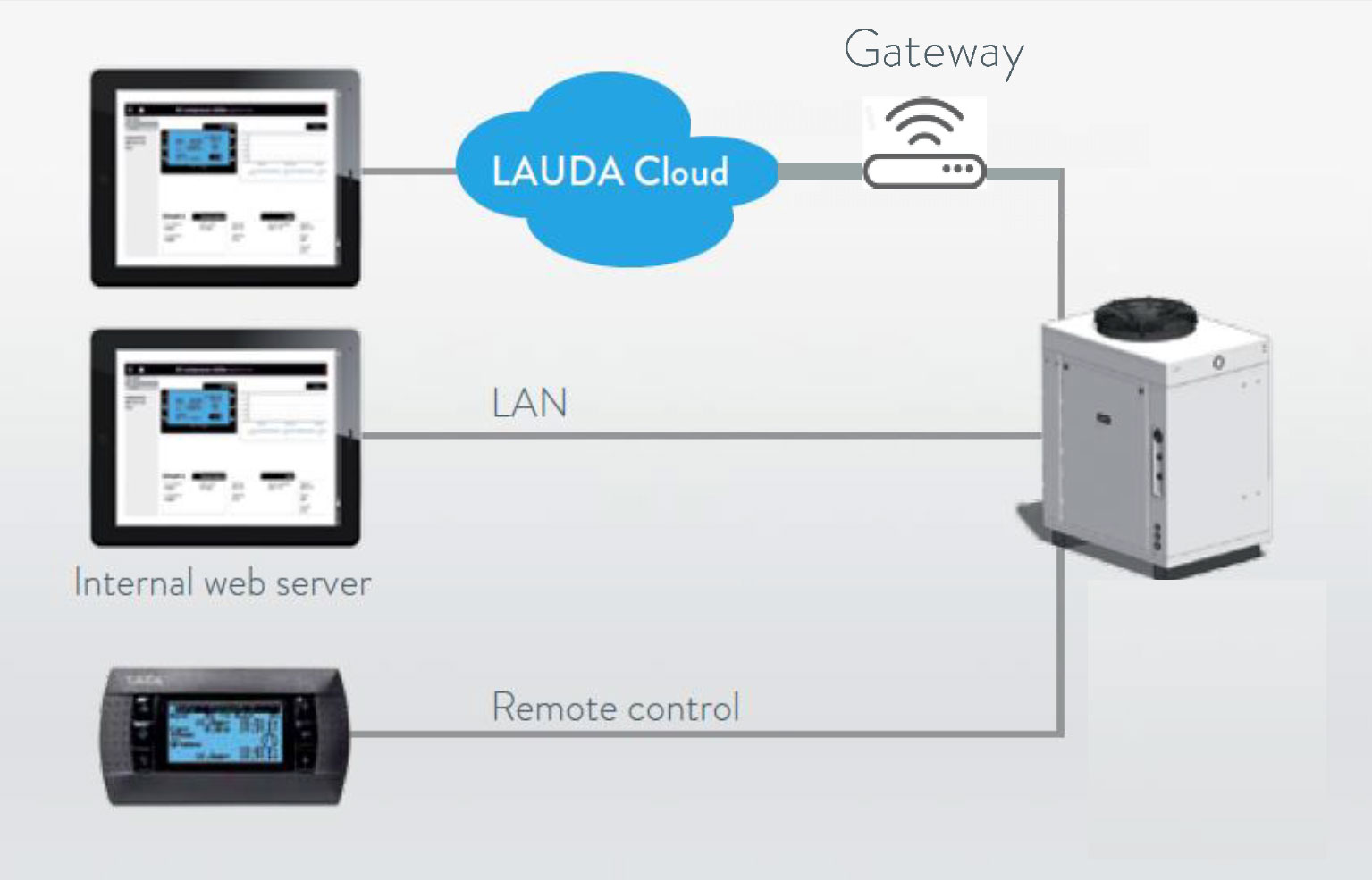

State-of-the-art connectivity

Optimized for Industry 4.0

Standard features include LCD remote control and Ethernet interface for connection to a computer or local network (LAN). These new models may also be controlled by a PC or mobile device via a web server with no internet connection required. Use the LAUDA CLOUD (accessory) for fluid data exchange, process monitoring, software updates, and remote troubleshooting anytime, anywhere.

Cost Savings

See how quickly your investment pays for itself

We compared energy consumption and procurement costs of the new Ultracool models to conventional circulation chillers of the same rated output to estimate payback time. The example calculations show how the new UC 24 delivers significant energy and cost savings.

LAUDA Ultracool UC 24

| Temperature profile (annual average temperature) |

Oslo / Helsinki / Stockholm (10 °C) | Amsterdam / London / Paris (15 °C) | Barcelona / Milan / Athens (20 °C) |

| Required cooling capacity | 22 kW | 22 kW | 22 kW |

| Outlet temperature | 10 °C | 10 °C | 10 °C |

| Energy costs | $0.138/kW | $0.138/kW | $0.138/kW |

| Working hours per year/day | 12 hrs / 260 days | 12 hrs / 260 days | 12 hrs / 260 days |

| Energy savings | 7913 kWh/year | 5384 kWh/year | 2716 kWh/yaer |

| Cost savings/year | $1,092.50 | $742.90 | $373.75 |

| Payback time | 11 months | 1 year, 4 months | 2 years, 7 months |